CraftStahl GmbH

Booth number: 6-4232

www.craftstahl.com

About us

CraftStahl develops machines that prove their worth under pressure – designed exclusively for the everyday reality of steel fabricators and steel traders.

Founded by industry professionals with decades of experience in international engineering, we know what it takes to keep operations running: tonnage, shifts, deadlines, and lean staffing.

Our portfolio combines robust construction with precise performance and seamless integration – fiber laser systems, welding robots, and roll forming solutions – all built to strengthen productivity and stability in daily use.

By uniting global efficiency with German engineering, we deliver technology that is identical in design, yet economically accessible. Every machine meets Western standards and certifications (CE, UL, cUL, OSHA) and integrates effortlessly into existing workflows and software environments (DSTV, DSTV+, IFC, Tekla, Advance Steel, ERP).

Where others build complexity, we bring clarity.

Where others disrupt, we integrate.

Because technology only proves its value when it performs – day after day, shift after shift.

CraftStahl · Making Technology Work for Steel.

Address

Penzberger Str. 12

82402 Seeshaupt

Germany

E-mail: info@craftstahl.com

Phone: +49 8157 5970903

Internet: www.craftstahl.com

Contact person:

Matthias Rummel

Managing Director

E-mail: sales@craftstahl.com

Matias Eckstein

Sales Manager

E-mail: sales@craftstahl.com

Products & Services

FritzLaser · Fiber Laser Systems for Steel Processing

More precision. More flexibility. Higher throughput. That’s how progress looks with fiber laser technology. FritzLaser systems deliver clean edges, minimal rework, and high cutting speed – increasing margins, not machine hours. Each model covers a specific application range, from heavy profiles to plates:

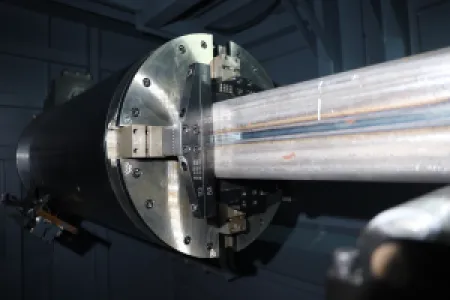

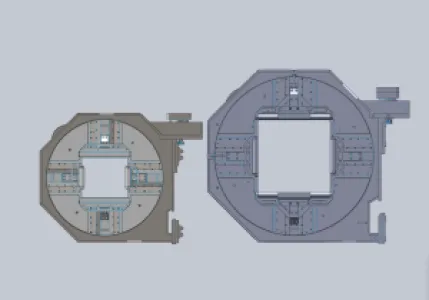

CastorCut 1200 – The heavy-duty solution for open profiles up to 1200 mm width and any length. Ideal for demanding notches and thick-walled sections.

CobraCut 550 – The master of flexibility for profiles 100 to 550 mm wide, up to 18 m long. Handles most steel-construction dimensions with speed and reliability.

CobraCut 360 – Productivity in the mid-range for profiles 50 to 360 mm wide and up to 12 m long. Compact footprint, high throughput.

CometCut – Flexibility instead of tool dependency. Replaces the traditional punch-and-shear line for profiles up to 250 × 250 mm and beyond – including square tubes and flat material.

KodiakCut – The modern solution for large-format plates. Laser replaces plasma and drilling, delivering cleaner edges, higher speed, and greater efficiency.

FritzWeld · Robotic Welding Systems

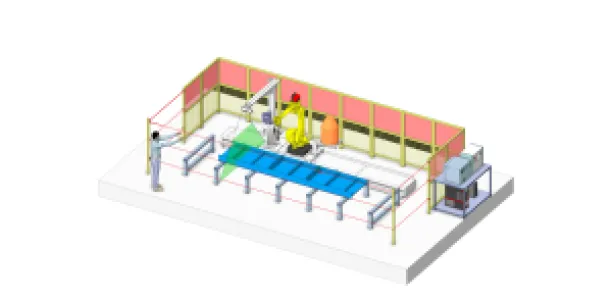

Predictable. Repeatable. Profitable. That’s production with welding robots. FritzWeld automates welding tasks with consistent quality – independent of operators. Vision and IFC systems ensure precise execution and reliable documentation.

WotanWeld – The robust welding robot with vision system. Automates typical welding tasks reliably and continuously – no drawings, no downtime.

WickyWeld – The compact cobot for maximum flexibility. Mobile design allows direct positioning next to heavy components for quick deployment and small-batch adaptability.

VikingWeld – The intelligent welding robot with 3D model integration. Works directly with IFC data to detect deviations between design and reality early, ensuring safe, efficient processes.

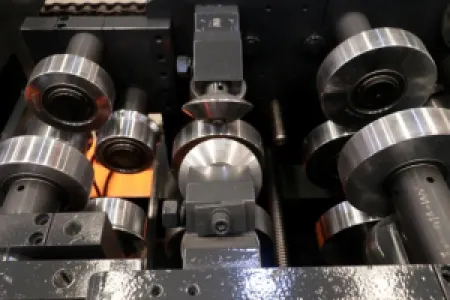

FritzForm · Roll Forming Systems

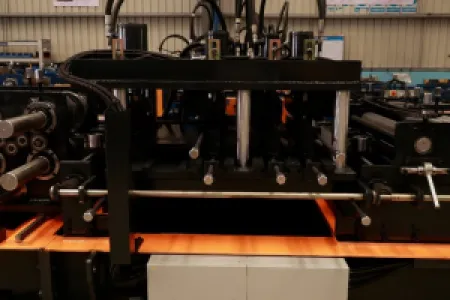

Broader range. Faster changeovers. Smarter investment. Roll forming that pays off. FritzForm makes roll forming profitable – even for variable profiles and small batch sizes. C-, Z- and U-profiles from 80 to 300 mm are formed with digital precision, minimal setup time, and consistent quality.

Fortis – Profitable even at small batch sizes. The roll forming system for modern steel processing – economical, flexible, and robust. Switch from C to Z in minutes, adjust material thickness and length digitally, and achieve up to 32 m/min production speed with servo drive and automatic straightening.