Kaltenbach GmbH & Co. KG

Booth number: 6-4236

www.kaltenbach.com

About us

With over 135 years of experience and 120,000 machines delivered worldwide, KALTENBACH is one of the leading suppliers of reliable, high-quality steel processing and preservation systems. The portfolio includes machines for sawing, drilling, thermal cutting, blasting and painting steel. With 300 employees at two production sites, nine subsidiaries and representatives worldwide, KALTENBACH offers its customers excellent local service. KALTENBACH belongs to Codymag, a strategic investor from Germany, which represents an established, large industrial group in mechanical and plant engineering.

Address

Blasiring 4

79539 Loerrach

Germany

E-mail: info@kaltenbach.com

Phone: +49 7621 175-0

Internet: www.kaltenbach.com

P.O. Box 122696

Saif Zone, Sharjah

United Arab Emirates

E-mail: info@kaltenbach.ae

Phone: +971 6557 4624

Internet: www.kaltenbach.com

Contact person:

Sriram Srinivasan

E-mail: s.srinivasan@kaltenbach.com

Products & Services

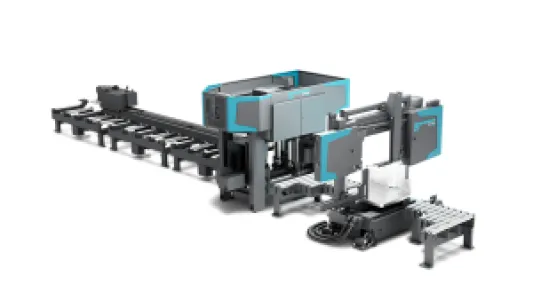

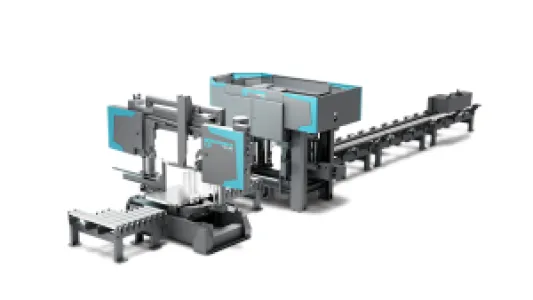

Saw-Drill- Combination S-Line: The Robust Entry-Level Solution

The S-Line is the ideal solution for companies looking to take their first steps into automated drilling and sawing. Compact, reliable, and designed for daily use – perfect for steel processors who want efficiency without complexity.

High cutting performance

Precise drilling up to Ø 32 mm / 1 1/4”

Proven, stable hydraulic saw feed

Compact, user-friendly and reliable system

Easy to operate

Precise setting of cutting angle

5-position automatic tool changer

Short Piece Gripper option

Smart to automate

Precise drilling up to Ø 32 mm / 1 1/4”

Saw motor 5.5 kW / 7.38 HP

Strong and secure material clamping system (vertical and horizontal)

Designed with essential milling features - ideal for standard applications

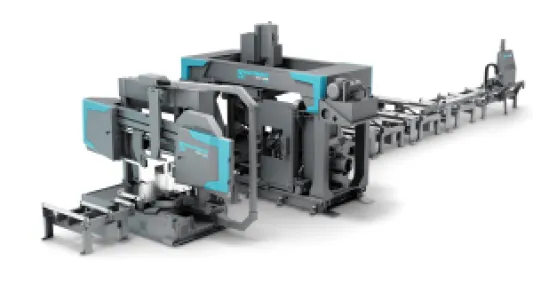

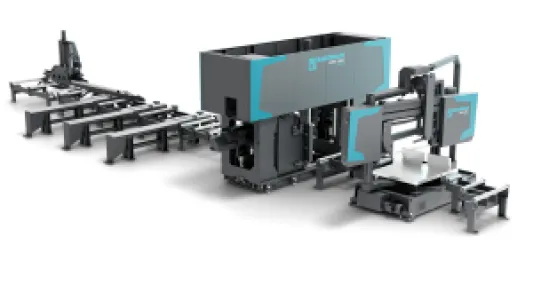

Saw-Drill- Combination M-Line: The Reliable Core of Your Production

The M-Line combines performance with versatility. Tailored for growing steel fabricators and traders who require higher output, more features, and seamless integration into their workflow.

FOR GROWING BUSINESSES WITH DIVERSE REQUIREMENTS

A powerful, versatile, and expandable system

Completely redesigned from the ground up – in line with the latest technical standards

Versatile processing with a high level of automation: drilling, milling, and layout marking on up to 4 sides, including center point marking

Movable sub-axis 300 mm / 12”, on 3 sides (independently)

Simultaneous processing across 3 axes

Suitable for 54 mm saw bands

Integrated intelligent material measurement

High-performance, newly developed sawing machine with a 54 mm / 2.1” saw band

High cutting performance

Precise drilling up to Ø 40 mm / 1.6”

Milling with movable sub-axis 300 mm / 12”

8-position automatic tool changer

Intelligent software solutions

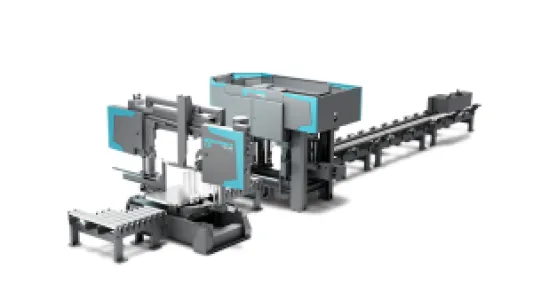

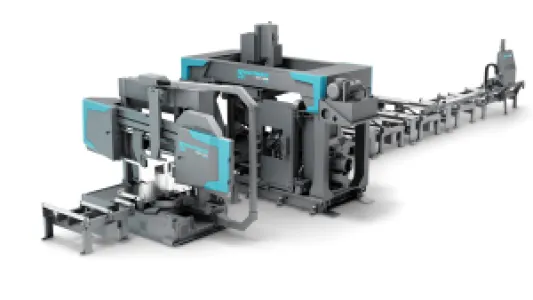

Saw-Drill- Combination P-Line: The Top Class for the Highest Demands

The P-Line is engineered for top-level performance in demanding environments. With maximum speed, precision, and automation capabilities, this system is the go-to choice for companies where output, uptime, and accuracy are key.

FOR HIGH-VOLUME, PERFORMANCE-DRIVEN OPERATIONS

A fast, fully automated, high-end system

Versatile processing with a high level of automation: drilling, milling, and layout marking on up to 4 sides, including center point marking

Movable sub-axis 500 mm / 20”, on 3 sides (independently)

Simultaneous processing across 3 axes

Suitable for up to 67 mm / 2.6” saw bands

Compatible with carbide saw bands & modular drilling systems

Optional CCT: Clear Cut Technology – the innovative table-lift function that effectively prevents the saw blade from jamming

Unique AS sorting solutions

Simultaneous sawing and drilling possible

The fastest saw on the market, with AFC as a standard feature

Precise drilling up to Ø 50 mm / 2”

Suitable for up to 67 mm / 2.6 “ saw bands, also carbide possible

Optional Clear Cut Technology CCT

12-position automatic tool changer

Ultimate machining diversity

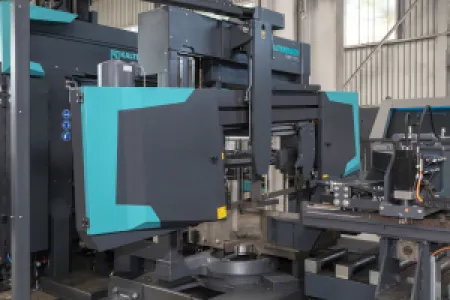

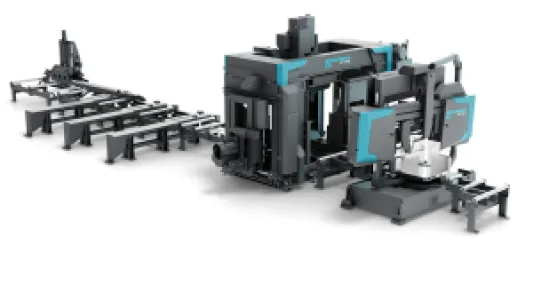

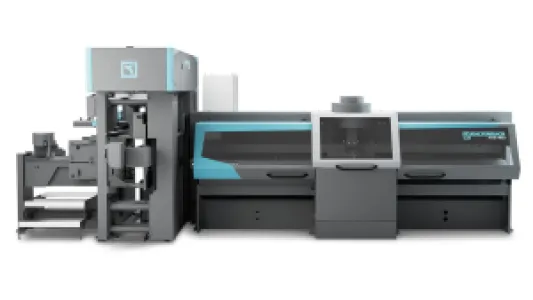

Fully automatic saw-drill system KKS 463 NA | KD 140

A TRUE ALL-ROUNDER.

THE SAW-DRILL SYSTEM FOR MAXIMUM VERSATILITY

The innovative KKS 463 NA | KD 140 saw-drill system combines all essential processing steps in a single machine – for a wide range of steel shapes: whether custom profiles, round or square material. Drilling (HSS and carbide), milling, thread cutting, flow drilling, or marking – fully automated, precise, and flexible on all four sides of the profile. Tasks that once required multiple machines and processing steps are now handled by a single, integrated system.

Maximum Flexibility and Cost-Efficiency

From round material with a diameter of 15 mm [0.6“] to special profiles up to 140 x 140 mm [5.5“ × 5.5“] – this machine covers almost all common materials and profile shapes. Miter cuts of up to ±20° make it highly versatile and perfectly suited for a wide range of applications – from steel construction and trading to metal fabrication. A minimum remnant length of 15 mm [0.6“] enable maximum material utilization.

Fully Automated with Minimal Staffing Requirements

Thanks to its high level of automation, setup time during material changes is virtually eliminated. Smart material buffering with automatic feed magazines and fully automated part sorting significantly boost productivity.